The Definitive Guide to Plastic Sheds Australia

The Definitive Guide to Plastic Sheds Australia

Blog Article

Plastic Garden Sheds Australia

A shed is typically a simple, single-story roofed structure, often used for storage, for hobbies, or as a workshop, and typically serving as outbuilding, such as in a back garden or on an allotment. Sheds vary considerably in their size and complexity of construction, from simple open-sided ones designed to cover bicycles or garden items to large wood-framed structures with shingled roofs, windows, and electrical outlets. Sheds used on farms or in the industry can be large structures. The main types of shed construction are metal sheathing over a metal frame, plastic sheathing and frame, all-wood construction (the roof may be asphalt shingled or sheathed in tin), and vinyl-sided sheds built over a wooden frame. Small sheds may include a wooden or plastic floor, while more permanent ones may be built on a concrete pad or foundation. Sheds may be lockable to deter theft or entry by children, domestic animals, wildlife. The simplest and least-expensive sheds are available in kit form. These kits are designed for regular people to be able to assemble themselves using commonly available tools (e.g., screwdriver). Both shed kits and DIY (do-it-yourself) plans are available for wooden and plastic sheds. Sheds are used to store home and garden tools and equipment such as lawn tractors, and gardening supplies. In addition, sheds can be used to store items that are not suitable for indoor storage, such as petrol (gasoline), pesticides, or herbicides. For homes with small gardens or modest storage needs, there are several types of very small sheds. The sheds not only use less ground area but also have a low profile less likely to obstruct the view or clash with the landscaping.

Old shed in Kansas

These small sheds include corner sheds, which fit into a corner (1 m × 1 m × 0.5 m or 3 ft × 3 ft × 2 ft—tall, wide, deep), vertical sheds (1.5 m × 1 m × 1 m deep, or 5 ft × 3 ft × 4 ft), horizontal sheds (1 m × 1.5 m × 1 m or 3 ft × 5 ft × 4 ft), and tool sheds. When a shed is used for tool storage, shelves and hooks are often used to maximize the storage space. Gambrel-style roofed sheds (sometimes called baby barns), which resemble a Dutch-style barn, have a high sloping roofline which increases storage space in the "loft" area. Some Gambrel-styles have no loft and offer the advantage of reduced overall height. Another style of small shed is the saltbox-style shed. Many sheds have either a pent or apex roof shape. A pent shed features a single roof section that is angled downwards to let rainwater run off, with more headroom at the front than the back. This is a simple, practical design that will fit particularly well next to a wall or fence. It is also usually lower than the typical apex shed, so could be a better choice if there are any height restrictions. A pent shed may be free-standing or attached to a wall (when it is known, unsurprisingly, as a wall shed).

An apex shed has a pointed roof in an inverted V shape similar to the roofline of many houses. Two roof sections meet at a ridge in the middle, providing more headroom in the centre than at the sides. This type is generally regarded as a more attractive and traditional design and may be preferable if the shed is going to be visible from the house.A twist on the standard apex shape is the reverse apex shed. In this design, the door is set in a side wall instead of the front. The main advantage of the reverse apex design is that the door opens into the widest part of the shed instead of the narrowest, so it is easier to reach into all areas to retrieve or store equipment.Larger, more-expensive sheds are typically constructed of wood and include features typically found in house construction, such as windows, a shingled roof, and electrical outlets. Larger sheds provide more space for engaging in hobbies such as gardening, small engine repair, or tinkering. Some sheds have small porches or include furniture, which allows them to be used for relaxation purposes. In some cases, remote workers who live in mild climates use small to medium-sized wooden garden sheds as outdoor offices. There is a growing industry in providing "off the peg" garden offices to cater to this demand, particularly in the UK but also in the US.

Shed owners can customize wooden sheds to match the features (e.g., siding, trim, etc.) of the main house. A number of decorative options can be added to sheds, such as dormers, shutters, flower boxes, finials, and weathervanes. As well, practical options can be added such as benches, ramps, ventilation systems (e.g., in cases where a swimming pool heater is installed in a shed), and electric lighting. Sheds designed for gardening, called "potting sheds", often feature windows or skylights for illumination, ventilation grilles, and a potter's bench for mixing soil and re-potting plants.

Materials

The main types of shed construction are metal sheathing over a metal frame, plastic sheathing and frame, all-wood construction (wood frame, wood siding and wood roof), and vinyl-sided sheds built over a wooden frame. Each type has various advantages and disadvantages that a homeowner has to consider. For example, while metal sheds are fire and termite-resistant, they can rust over time, or be severely damaged by high winds or heavy snow loads. Wood sheds are easier to modify or customize than plastic or metal because carpentry tools and basic carpentry skills are more readily available. Vinyl-sided, wood-framed sheds blend the strength of a wood frame with the maintenance-free aspect of vinyl siding (it does not need to be painted or varnished). The International Building Code (IBC) defines a shed as a building or structure of an accessory character; it classifies them under utility and miscellaneous group U (Chapter 3 Section 312).[citation needed] Metal sheds are made from thin sheet metal sheathing (galvanized steel, aluminium, or corrugated iron) attached to a metal frame. Metal sheds are a good choice when long-term strength and resistance to fire, rot, or termites are desired. However, metal sheds may rust over time, particularly if they are constructed from steel that is not galvanized. Be aware that concrete is highly corrosive so care needs to be taken when assembling your shed to avoid contact with the outside panels.[8]

As well, some types of metal sheds that have thin walls are easily dented, which may make some types of thin metal sheds a poor choice for vandal-prone areas or for high-traffic activities such as small businesses. In cold climates, metal sheds with thin walls need to have snow and ice cleared from the roof, because the thin metal may be damaged by a heavy accumulation. Since thin metal sheds weigh much less than wood or PVC plastic sheds, thin metal sheds are more at risk of being damaged by heavy winds. To prevent wind damage, thin metal sheds should be attached to a concrete foundation with screws.[9] In countries where the climate is generally mild, such as Australia, very large metal sheds are used for many types of industry. Corrugated metal sheds may be better able to withstand wind and snow loads, as the corrugated shape makes the metal stronger than flat tin.

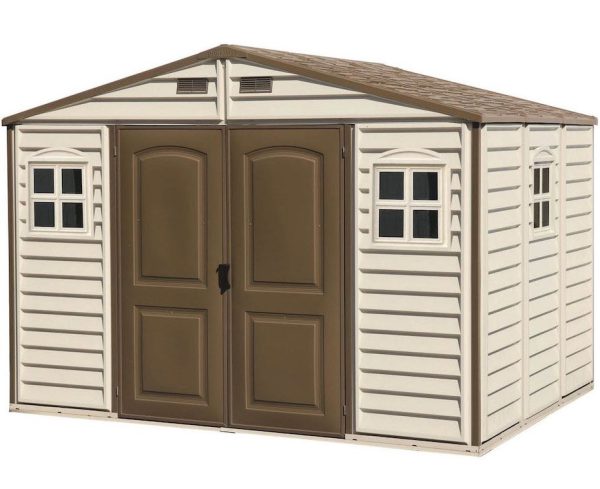

Plastic

Lifetime brand blow-molded plastic sheds

Plastic shed kits utilizing heavy molded plastics such as PVC and polyethylene may be less expensive than sheet-metal sheds. PVC resins and high-impact, UV light-resistant polyethylene make plastic outdoor sheds stronger, lighter, more durable, and more resistant to denting and chipping than wood, and tend to be more stable. Plastic shed kits sided with vinyl are typically among the least-expensive types of shed construction. Higher-quality sheds use UV-resistant plastic and powder-coated metal frames. Many plastic sheds are modular to allow for easy extensions, peg-boards, shelving, attic-storage, windows, skylights, and other accessories to be added later if these additions are purchased from the manufacturer.

Plastic sheds are not susceptible to termite or wood-boring insect damage, and they require little maintenance. Being rot-proof they do not need to have preservatives applied. This makes them preferable in climates where the weather can be changeable, such as the United Kingdom.[10] Unlike wooden or metal sheds, which often require a permit to build, in many areas, plastic sheds do not. However, this is something property owners will need to verify. A call to your council/town's planning or building code office can provide information on permits. Wooden sheds have a natural look that can blend in well with garden environments. Despite the strength of wood, over time, untreated and neglected wood can rot, split, warp or become susceptible to mold and mildew, so wood sheds should be treated for protection with stain and varnish. Wood sheds need regular maintenance. This includes keeping plant matter and debris from piling up beside the walls and on the roof, and occasional rot-proofing with preservatives. Sheds are sometimes also re-stained or Plastic Sheds Australia varnished at times for aesthetic and wood protection reasons. Fire and, in some regions, termite attack are also potential problems.

Stains and preservatives can be applied to wood sheds to prevent damage to the wood caused by exposure to rain, damp ground, UV light, harsh climatic conditions, fungal attack and wood-boring insects. If a coloured preservative oil or stain is used, a wooden shed can either be made to stand out as a feature within a garden, or to blend in with its surroundings. Red cedar coloured stain is popular. Legislation such as the European Biocidal Products Regulation has reduced the number of effective active ingredients available for wood preservative formulations. For this reason, in recent years, there has been a greater emphasis on preserving wood by keeping it dry, for example through the application of water-repellent "wood protection creams."

Some types of wood, such as cedar, are more naturally resistant to water damage.When looking for a wooden shed, it is important to understand the difference between the two types of preservative used in their manufacture. The timber will have been treated in one of Plastic Sheds Australia two ways: dip treatment or pressure treatment. Dip-treated sheds are made from components that are lowered into a tank of preservatives before the panels are assembled. This is a quick and simple Plastic Sheds Australia process that keeps costs down and encourages manufacturers to produce a wide variety, making dip-treated sheds the most popular and affordable type on the market. They are easily recognisable by their golden brown colour, which is due to a dye added to the preservative. Most manufacturers offer a 10-year anti-rot guarantee on dip-treated sheds, but they have to be re-coated every year or two.

Pressure-treated sheds are made from timber planks that have had the moisture sucked out of Plastic Sheds Australia them under vacuum conditions in a special cylinder. A powerful preservative is then forced into the wood at high pressure until it is absorbed deep into the grain, becoming an integral part of the timber. This provides excellent protection against the weather—so much so that manufacturers generally give a 15-year anti-rot guarantee. These sheds are usually distinguished by a pale green tinge which will fade eventually to a silvery grey. Although pressure-treated sheds tend to be more expensive than dip-treated ones, their big advantage is that they will not need any further preservative treatment during the guarantee period, saving owners time and money.

One advantage of using wood sheds over metal versions is that it is easier to modify them by adding windows, doors, shelving, or exterior trim (etc.) because wood can be cut and drilled using commonly available tools, whereas a plastic or metal shed requires specialized tools. Some homeowners may prefer wood sheds because wood is a renewable resource.

Report this page